Testing Capacitors

- Craig Migliacco

- Apr 18, 2019

- 3 min read

Updated: Nov 20, 2023

An HVACR capacitor can be tested after turning the power off, disconnecting the wiring, and bleeding off any leftover voltage before testing. This can be done with a multimeter on the uF or MFD setting.

On a run capacitor, most of the voltage will drain off from the capacitor during the off cycle of the motor. This is because the run capacitor is attached to the motor while it is still spinning after the voltage is shut off.

In the case of a start capacitor, the voltage will still be stored by the capacitor unless there is a bleed resistor permanently installed between the two terminals of the capacitor. If there is no bleed resistor, the start capacitor will store voltage because a component such as a potential relay, a PTC thermistor or a current starting relay has kicked the capacitor out of the electrical circuit during the first fraction of a second of run time while it still has voltage in it.

A run capacitor is usually round or oval and silver or gray but it can also be a rectangle shape and black. Start capacitors are typically round and black.

Capacitors can be visually checked prior to measuring for uF/mfd. The capacitor is known to be bad if it has one of the following visual clues:

1. dielectric fluid leaking out of the capacitor

2. the top cap on the capacitor is moist with oil

3. there is a mushrooming of the top cap of the capacitor

4. the capacitor body looks expanded

A capacitor can be bad even if it shows no obvious signs of a problem. To test a capacitor, turn off the power to the unit, note which terminals the wires are connected to, and disconnect the wires. Finish discharging the capacitor using a 10,000 to 20,000 ohm resistor across the terminals from C to Herm and C to Fan. (If the terminals are rusty, a file can be used to expose the bare metal at the contacts.) If a resistor is not available, the capacitor could be shorted by holding onto the plastic part of a screwdriver and place the unpainted metal edge of the screwdriver from the C to Herm and from the C to the Fan. If the capacitor is not a dual run capacitor with three taps then it is a standard single capacitor with only two taps. Simply place the resistor across the two taps to discharge the voltage. If the voltage is not discharged, the multi-meter will not be able to read the capacitance in uF MFD.

In order to determine if the capacitor is good, the uF MFD should be within 5 to 6% of the rated uF MFD storage capacity stamped on the side of the capacitor. If the capacitor is visually bad or if the measurements are outside of the 5 to 6% of the rated capacitance, the capacitor should be replaced. The capacitor should be replaced with a new one that has the exact same uF MFD rating as the old one. The voltage rating must be the same or higher than the old one.

If the capacitor ratings are worn off of the old capacitor, look for a uF MFD rating on the side of the condenser fan and the compressor.

The compressor is always higher than the fan MFD. To measure the herm part of the capacitor, place one multimeter probe on the C terminal and one probe of the Herm terminal. Wait ten seconds for an accurate reading. To measure the Fan part of the capacitor, place one probe on the Fan terminal and the other probe on the C terminal. If the capacitor is just a single capacitor then there are only two terminals. It doesn’t matter which probe is placed on what terminal. Also when wiring back in the new capacitor, it doesn’t which side of the capacitor is the inlet and which one is the outlet voltage.

To learn more about HVACR capacitors, view these videos-

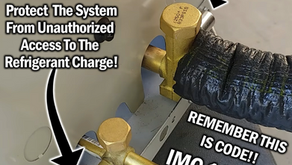

Check out our book “Refrigerant Charging and Service Procedures for Air Conditioning”.

The full outline is available at https://www.acservicetech.com/the-book

If you have already purchased our book, be sure to tell local HVACR Instructors about our book and what you think of it. We would love to get the book into the hands of the next generation of HVACR Technicians!

Published: 4/18/2019

Author: Craig Migliaccio

About the Author: Craig is the owner of AC Service Tech LLC and the Author of the book “Refrigerant Charging and Service Procedures for Air Conditioning”. Craig is a licensed Teacher of HVACR, Sheet Metal, and Building Maintenance in the State of New Jersey of the USA. He is also an HVACR Contracting Business owner of 15 years and holds an NJ HVACR Master License. Craig creates educational HVACR articles and videos which are posted at https://www.acservicetech.com & https://www.youtube.com/acservicetechchannel

.png)

Nice technical post! Your breakdown of tools and methods was very practical. I also came across a coversinplay-based https://www.coversinplay.com blog discussing similar mechanical techniques, which added extra perspective.

Great explanation of copper tube bending tools and methods. The practical breakdown makes it easy to understand even for those newer to the topic. I’ve seen a similar technical comparison discussed on a ninexpower-based https://www.ninexpower.com blog, and this article complements that information very well.

This is an excellent guide on testing capacitors — very clear and detailed, and the safety tips were particularly helpful. I appreciated the step-by-step explanations, which make it easier for beginners and hobbyists to follow. I recently saw a related discussion on a samedaydiplomas blog https://samedaydiplomas.com/ that added a useful perspective on learning technical skills in a structured way. Really appreciate you sharing such informative content!