Newer Methods that Make us Better Techs and Reduce Labor and Frustration! Top 15!

- Craig Migliacco

- Oct 10, 2019

- 5 min read

Updated: Nov 20, 2023

Newer or faster methods do not always require expensive tools but do require a certain tool setup and step by step procedure. Some of the most labor intensive and time consuming procedures that we perform are checking the refrigerant charge, adding refrigerant, vacuuming a system, and recovering refrigerant. Not only can these procedures be done faster but we can perform them in such a way that will reduce frustration and lower the possibility of contamination in the system.

Below are some of my top recommendations for performing service on a refrigerant based system.

1. Vacuum an empty system using a two hose setup without attaching the manifold gauge set. The removal of the manifold gauge set from the vacuum setup will reduce the potential for leaks and speed up the vacuum process because there are less restrictions, turns, and hoses.

Related video: https://youtu.be/J4QvgpYFS9U

2. Keep the vacuum gauge as close to the system as possible so that you can read the true vacuum level inside the system, not just the vacuum level in the hose near the vacuum pump.

3. Use three valve core removal tools in the vacuum setup. One valve core removal tool is used on each of the two ports. The third valve core removal tool is used to valve off the vacuum gauge before breaking the vacuum with refrigerant from the system or the bottle.

4. Make sure to valve off the vacuum gauge from the vacuum setup before breaking the vacuum with refrigerant from the bottle or system. This will guard the vacuum gauge sensor from being contaminated with refrigerant oil. If the sensor becomes contaminated, it will no longer read an accurate vacuum level or may not read a vacuum level at all. If the sensor becomes contaminated, it must be cleaned using the manufacturer’s cleaning method. In some cases, the method is to use rubbing alcohol but always follow the manufacturer’s procedure.

5. Perform a 10 minute standing vacuum test to verify that no water, air, nitrogen, or leaks exist in the system. After the 10 minute standing vacuum test, break the vacuum with refrigerant from the bottle or from the system.

6. While performing a recovery on a system, run the indoor blower motor to introduce heat at the indoor coil. During recovery, running the indoor blower helps vaporize liquid refrigerant in the system. This allows the technician to measure the true pressure in the system. It also reduces the possibility of the pressure rising after the recovery is performed.

7. During the vacuum, if the indoor blower motor is running, heat is introduced at the indoor evaporator coil. This reduces the possibility of water freezing during the vacuum procedure. This is only needed when vacuuming a system with high water content in the tubing.

8. A triple evacuation does not need to be performed if during the standing vacuum test of a single evacuation, the vacuum level does not rise. For instance, if you vacuum down to 200 microns and the vacuum level does not rise during the standing vacuum test with the vacuum pump off, the system is verified as having no air, nitrogen, water, or leaks. The triple evacuation is only needed if the technician is having a hard time removing the moisture from an empty system.

9. Recover refrigerant using valve core removal tools at the system ports to remove the valve cores. This allows the technician to measure the true pressure in the system while the recovery machine is running.

Related video: https://youtu.be/os9gKLf7LJg

10. Use a recovery machine capable of measuring the systems’ pressure so that you don’t need to attach the manifold gauge set in the setup. Recover from both sides of the system. Use a tee or another valve core removal tool to connect the vapor and liquid hoses prior to entering the inlet of the recovery machine.

11. Use a short hose to connect from the outlet of the recovery machine to the inlet of the recovery bottle. A short hose that has a slightly larger interior diameter will allow the recovery machine to not work as hard. Make sure a valve core depressor is not in the end of the hose as this would restrict the flow. Remember that the leftover refrigerant in this hose cannot be pumped into the recovery bottle because the bottle will be at the same pressure as the hose. This is another reason to keep this hose short. This reduces the amount of refrigerant that escapes into the air when disconnecting from the valved off recovery tank when complete.

12. Using quick connect test gauges or quick probes to check a refrigerant charge is a big benefit for the technician. This reduces the time it takes to disconnect from the system since you don’t have to perform a disconnect procedure to charge the liquid from the red high side hose into the low side before disconnecting the low side hose.

Related video: https://youtu.be/4oE3pkhJynQ

When using the test gauges or electronic probes, there is no need to purge air from any hoses since hoses are not used.

Since you don’t have to purge air or perform the disconnect procedure, this reduces the possibility of contamination in the system from any old refrigerant oil in the hoses.

Related video: https://youtu.be/eI_neAZkKYw

13. When checking the charge with Test probes or electronic probes, use tees to add refrigerant or recover refrigerant while the system is running.

If a small amount of refrigerant needs to be recovered from a running system to adjust the charge, the system’s compressor can allow the technician to recover refrigerant from the liquid port. Make sure to not recover much refrigerant this way since oil is removed from the system along with the refrigerant.

14. Leak checking the valve cores can be done very easily using a cap with a small hole drilled in the end and bubble leak detector applied to the cap end. Using the cap with a hole in the end will not allow any bubble leak detector to enter the port and valve core area. If there is leak, the technician will see the bubble being blown very quickly.

Related video: https://youtu.be/xyBM4PLQXK0

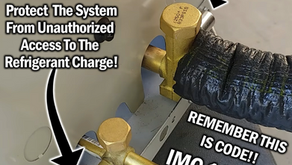

15. If there is a leaky valve core on a system with a full refrigerant charge, replace the valve core with the valve core removal tool without having to recover refrigerant from the system.

Related video: https://youtu.be/vmtlfcEr0is

Check out our book “Refrigerant Charging and Service Procedures for Air Conditioning” where we go step by step through the vacuum procedure as well as all the other procedures, checking the charge, and troubleshooting tips used when working with refrigerants. The full outline is available at https://www.acservicetech.com/the-book If you have already purchased our book, be sure to tell local HVACR Instructors about our book and what you think of it. We would love to get the book into the hands of the next generation of HVACR Technicians!

Published: 10/10/2019 Author: Craig Migliaccio

About the Author: Craig is the owner of AC Service Tech LLC and the Author of the book “Refrigerant Charging and Service Procedures for Air Conditioning”. Craig is a licensed Teacher of HVACR, Sheet Metal, and Building Maintenance in the State of New Jersey of the USA. He is also an HVACR Contracting Business owner of 15 years and holds an NJ HVACR Master License. Craig creates educational HVACR articles and videos which are posted at https://www.acservicetech.com & https://www.youtube.com/acservicetechchannel

.png)

Reviews describe tactile balance during posing and rest. Care tips maintain texture and comfort through gentle cleaning. In a central note readers can check BetterLove here to see thoughtful material choices. Positive experiences emphasize safety consistency and enjoyment. Clear descriptions set comfort goals and reduce surprises. Supportive brands focus on care education and friendly service that strengthens satisfaction for owners seeking calm confidence and reliable enjoyment across everyday use and quiet moments at home with trust built through honest communication and caring support teams available whenever needed for peace of mind.

Great tips - these methods really show how small changes in setup and procedure can save time, reduce frustration, and protect the system. Keeping gauges close, using valve core tools, and running the blower during recovery are smart ways to get more accurate readings and avoid contamination. It’s a nice reminder that efficiency isn’t just about fancy tools - it’s about working smarter and protecting your work.

Tip 13 is interesting. By adding those "Tees," you are actually "building" your own analog manifold gauge set! Any downside to using this method compared to using standard analog manifold block with hoses? I like the idea of not having to purge as well as not having to charge the refrigerant in the hoses back into the unit!

Wow you put a lot of work into this post. Thanks! Priceless info.

Hi Craig and thank you for everything you do. I recently changed out a TXV because it was showing symptoms of being stuck in the closed position. When I installed the new one after pressure testing and evacuation the superheat was 3 degrees. Why is that and how do I fix it?

Marco Sylvia