EEV Electric Expansion Valve Training Project

- Craig Migliacco

- Mar 29, 2023

- 5 min read

Updated: Dec 19, 2024

Explaining how an EEV operates is much easier when you can show exactly what is happening, each step of the way. This project is meant to simplify the operation of the EEV by visually showing the internal pin movement as 12V power is temporarily applied to each of the 4 electrical coils in sequence.

Why does the EEV Matter?

The EEV is one of the most important parts in a modern inverter system. This metering device is responsible for reducing the pressure of the refrigerant flowing through an HVACR system. Part of what makes this particular part so effective at performing its job is the fact that it is electrically controlled by powering the head, in order to make small changes to internal pathway size within the body. However, because it is electrically controlled, it can be a challenge to visualize what is going on within the EEV head and in the body. Fortunately, this project is designed to help students understand exactly what is taking place within the EEV and how it effects the flow of refrigerant. To learn more about the EEV, watch this video: https://youtu.be/LzvVjvUpOVM and to learn more about inverter mini splits, check out our book: https://www.acservicetech.com/mini-split-book

Building the Display

An EEV training project can be built in a number of ways, using a variety of different materials. For this example, the tools, parts, and steps are listed below:

Tools Required

Standard Drill

1/4" Drill Bit

1/4" Hex Bit

Rotary Tool with grinding blade

Wire cutter/stripper

Parts Required

3/4" x 6" backing board (plywood or vinyl work well)

1/4" zip screws

8 - AA Batteries

1 - AA Battery holder case 1.5V x 8 for 12V: https://amzn.to/3JCDiLj

2 - Command strips: https://amzn.to/422OOqy

1 - Multimeter probe: https://amzn.to/3ZNigiI

5 - One hole metal strap: https://amzn.to/3mLmmJH

1 - 16-22 gauge wire nuts: https://amzn.to/3ZP1gZI

1 - Electric Expansion Valve: https://www.partstown.com/parts?q=electric+expansion+valve

Step #1

Cut an 8" length out of the backing board. This will be the base for building the remainder of the project.

Step #2

Using a vice (or similar equipment), flatten the (5) one hole metal straps.

Step #3

At this point, it's a good idea to do a rough layout of the parts to ensure everything fits and that the tabs, wires, batteries, and EEV are all in the proper location.

Step #4

Next mount the AA battery holder case using the command strips. Make sure the wires are accessible for connection to the EEV and probe.

Step #5

Cut the end off a multimeter probe and wire nut the end of the probe to the red wire from the battery holder.

Step #6

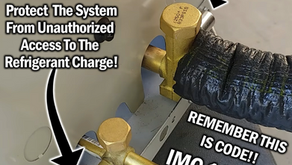

A new or used EEV can be used. Make sure the body of the EEV is disconnected and non-pressurized. Remove the electrical head from the EEV body. Next, mount a tubing cutter to the stainless steel shell and cut roughly an inch off the top of the shell in order to expose the permanent magnet on the inside. Make sure to turn the handle of the tubing cutter slowly as to not crush the shell onto the inner permanent magnet. Once this is complete, rotate the inner permanent magnet counterclockwise (in most cases) to rise the pin upward. Next, while wearing safety glasses and other proper PPE (Personal Protective Equipment), use a rotary tool or small grinder to carefully grind down the EEV body in order to expose the pin and the tubing pathway.

Step #7

While the head is off the EEV body, using a rotary tool with a cutting wheel, cut the cap off the head of the EEV. Below is pictured a completely intact EEV head (right) and the EEV head after having the cap is cut off (left).

Step #8

After the EEV head and EEV body have been prepared, drill two holes on an angle for the EEV tubing to rest in.

Step #9

Place the EEV head back on the EEV body. Then set the EEV in the drilled holes. While in place, make sure the wiring from the EEV head will reach the correct location for the one-hole metal straps. Cut the wires to length and strip the ends. (Note: It is good practice to leave the wires from the EEV head long until the final sequence is determined.)

Step #10

Determine the correct sequence for the wires. This can be done by measuring for resistance across the wires to identify the common wires. (Refer to this video https://youtu.be/LzvVjvUpOVM and/or our book for a full explanation of this process.) EEV's may have similar color coding, and in those cases, the wire coloring sequence in the pictures within this article can be used. Once the common wire/wires have been identified, mount them, along with the black wire from the battery holder, under a single one-hole metal strap. This should be mounted near the bottom of the board, out of the way. Alternatively, these two or three wires (depending on if the EEV is a 5-wire or 6-wire) can be wire nutted together and secured out of the way. A 5-Wire EEV has a single common wire. A 6-Wire EEV has a two common wires.

Step #11

Using the flattened one-hole metal straps, mount the remaining wires loosely. Once the wires have been mounted, determine the final order of the remaining wires. Once the order has been finalized, snuggly secure the wires to the tabs.

Using the Display

After the display is complete, turn on the battery power using the switch on the side of the battery case. The project is ready for teaching! If you are interested in learning more about how these displays work and how they can be used for instructing, check out the video below or purchase our Inverter Mini Split Operation and Service Procedures book available on our store!

If you want to know more about Inverter Mini Splits, check out our Book!

Check out our free Quizzes to test your knowledge here!

Check out our Free Calculators here!

If you want to learn about inverter mini split systems, check out our "Inverter Mini Split Operation and Service Procedures" book!

If you want to learn about refrigerants and how they work in a system, check out our “Refrigerant Charging and Service Procedures for Air Conditioning” book . Test your knowledge with our 1,000 question workbook along with the answer key! We also have quick reference cards for use out in the field! Bundle Packs are a great way to save and get faster shipping! Check out www.acservicetech.com/store

Tools that we use: www.amazon.com/shop/acservicetech

Tools that we use: https://www.trutechtools.com/?affid=8 6% off coupon code "acservicetech"

Published: 3/29/2023

Author: Craig Migliaccio

About the Author: Craig is the owner of AC Service Tech LLC and the Author of the book “Refrigerant Charging and Service Procedures for Air Conditioning”. Craig is a licensed Teacher of HVACR, Sheet Metal, and Building Maintenance in the State of New Jersey of the USA. He is also an HVACR Contracting Business owner of 17 years and holds an NJ HVACR Master License. Craig creates educational HVACR articles and videos which are posted at https://www.acservicetech.com & https://www.youtube.com/acservicetechchannel

.png)

Random Name Generator is a well-known online tool that blends utility, creativity, and simplicity into a straightforward but effective experience. The user interacts with the generator to instantly produce unique and fitting names for characters, projects, or creative endeavors in this tool.

This was a surprisingly clear and helpful technical breakdown. The practical approach made it easy to follow. I recently came across a trentonjonesmd-style https://trentonjonesmd.com/ review blog that also explained complex tools in a very accessible way.

Clear and informative explanation. You broke down technical details in a very accessible way. It reminded me of a practical trade-focused guide I saw on an easylawinc-based https://www.easylawinc.com blog.

This post is very informative for anyone working with copper tubing. Your explanations of the tools and techniques were clear and precise. I recently came across a docsoutsidethebox https://www.docsoutsidethebox.us discussion on metalworking methods, which offered some complementary tips. Excellent resource!

This is a really informative post! I appreciated the clear explanation of tools and methods. I also came across a harleystreetpremierconsultingrooms-based https://harleystreetpremierconsultingrooms.co.uk discussion that touched on practical techniques, which complemented your points nicely.