Clogged Liquid Line Filter Drier?

- Craig Migliacco

- Aug 19, 2020

- 4 min read

Updated: Feb 25, 2025

How can you tell if you have a clogged liquid line filter drier? If there is a noticeable temperature drop from one side of the filter drier to the other, this means that there is a pressure drop. Remember that temperature follows pressure and temperature is something that we can measure on the outside of the tubing. Usually no ports are available at the inlet or outlet of the liquid line filter drier.

Filter driers are designed to have an extremely low pressure drop across them even while filtering down to 25 microns and trapping both moisture and acids. On most residential systems with a newer filter drier, the temperature drop may be around .5 degree temp drop or less from one side to the other. Often, this occurs because of the large surface area of the filter drier itself exchanging heat with the surrounding air and not due to any pressure drop. It is hard to pinpoint an actual number to say that this means that there is a clog in the filter drier. However, if you do measure the correct subcooling at the outdoor unit, a high total superheat, a low delta T at the indoor coil and there is a few degree temperature drop across the filter drier, then figure on replacing the filter drier!

In the example above, the R-22 system has a low side sat temp of 22°F and a vapor line temp of 66.7°F

Total Superheat = Vapor Line Temp - Low Side Sat Temp

Total Superheat is 66.7 - 22 = 44.7°F

In the example above, the R-22 system has a high side sat temp of 97°F and a liquid line temp of 82.6°F

Subcooling = High Side Sat Temp - Liquid Line Temp

Subcooling is 97 - 82.6 = 14.4°F

Because the system in the previous two pics has a high superheat and a normal to high subcooling, this signals that the system is not low on refrigerant and actually has some type of restriction in the liquid line. To tell the difference between a low refrigerant charge and a clog in the liquid line, the technician will need to measure the subcooling. If the subcooling is correct or high while the superheat is high, this means that there is a liquid line restriction problem. If the subcooling is low and the superheat is high, this means that the refrigerant charge is low. If it is determined that there is a liquid line restriction, the technician must investigate to determine which component is the problem on the liquid line. We usually start by measuring the temp drop across the filter drier.

If the filter drier is partially clogged, there may be a few degree temp drop across it.

However, if the filter drier is completely clogged, there will be a large temperature drop across it and likely frost due to the low temp of the refrigerant exiting the clogged filter drier. Remember that if there is a temp drop across the filter drier, the liquid refrigerant is being restricted and partially flashing to a gas before making it to the metering device. The metering device is the restriction that should control the pressure drop and expansion of the refrigerant. A restricted filter drier will not allow enough refrigerant to get to the metering device. The clog will also not allow the refrigerant to be in the subcooled state as the refrigerant enters the metering device. Because of this, there will not be enough refrigerant exiting the metering device and entering the evaporator coil in order to absorb the heat from the air crossing the outside of the coil. This will always result in a high superheat at the evaporator coil.

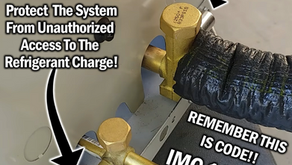

Even if the filter drier is not the problem, remember to always replace it any time another refrigerant based component is replaced! The filter drier has a limited capacity for water storage so it should always be replaced any time the system is opened to atmospheric pressure. After recovering the refrigerant or pumping down the system, make sure to cut the filter drier out instead of sweating it out with a torch. Heating the old filter drier will result in the moisture within the filter drier to boil out, escaping into the system's tubing. You can avoid this by simply cutting out the old brazed-in-filter-drier and brazing in a new one. Other types of filter driers can be replaced with different methods. Some have flare connections and larger commercial filter driers have a replaceable core so that the replacement of the outer shell is not needed.

To learn more about troubleshooting liquid line restrictions, check out this video below! Also check out our book for a full guide of troubleshooting scenarios while measuring the refrigerant charge!

To learn more about step by step procedures, check out our Book or E-book and test your knowledge with our 1,000 question workbook along with the answer key! We also have quick reference cards for use out in the field! Bundle Packs are a great way to save and get faster shipping!

Check out our free quizzes to test your knowledge here!

Check this article out on Liquid Line Restrictions!

If you want to learn the full Total Superheat Charging Method, check out this article!

If you want to learn the full Subcooling Charging Method, check out this article!

If you want to learn about Delta T, check out this article!

Tools that we use: www.amazon.com/shop/acservicetech Follow us on Facebook for Quick Tips and Updates here! Published: 8/19/2020 Author: Craig Migliaccio

About the Author: Craig is the owner of AC Service Tech LLC and the Author of the book “Refrigerant Charging and Service Procedures for Air Conditioning”. Craig is a licensed Teacher of HVACR, Sheet Metal, and Building Maintenance in the State of New Jersey of the USA. He is also an HVACR Contracting Business owner of 15 years and holds an NJ HVACR Master License. Craig creates educational HVACR articles and videos which are posted at https://www.acservicetech.com & https://www.youtube.com/acservicetechchannel & https://www.facebook.com/acservicetech/

.png)