Can you Braze Mini-Split systems instead of Flaring them?

- Craig Migliacco

- Sep 12, 2019

- 4 min read

Updated: Jun 26, 2023

I have been asked, “Can we braze mini-split systems instead of flaring them?”. The answer, technically, is yes. The only question is in a warranty situation, will the manufacturer accept an indoor unit with the flares cut off? In most cases, they should accept them and the manufacturer reps that I have spoken with have said that it is not a problem. However, technicians should verify this themselves with the manufacturer of the particular equipment that they install.

Of course, when we braze copper line set, we make sure to flow nitrogen or another inert gas through the tubes so that oxidation does not occur inside the line set. The technician will still need to flare the connections to the outdoor unit since there are no stubs to braze, only service valves with flare connections. There is usually only one service port at the outdoor unit, and it is on the vapor service valve. This is where the nitrogen will be introduced. Make sure the small, liquid line is not connected to the flare connection on the liquid service valve. The nitrogen will exit out of this small, liquid line tube.

Step by Step Process of Brazing Mini-Split Tubing:

1. The technician will begin by flaring the large suction line tube and connecting this to the outdoor unit. The small, line set tube should not be connected at this point but will remain open on the end. (The small line set tube would be referred to as the low pressure liquid tube since the active metering device is usually in the outdoor unit of a mini split system. This means that during cooling mode, the metering device will lower the pressure of the refrigerant before it enters the small line set tube.)

2. The flare connectors will need to be cut off of the indoor unit copper stubs and the copper tubes must be reamed in the downward position so that any small pieces of copper will fall out of the tube.

3. The copper stubs from the indoor unit should be swaged and the large and small line set tubes should be run into place and inserted into the swages.

4. Next, a flow regulator must be connected onto a nitrogen tank and set to flow at 2-3 CFH (cubic feet per hour). The nitrogen hose will then be connected to the outdoor unit vapor service port. The nitrogen will enter the vapor service port, flow through the large vapor line, through the evaporator coil, and out of the small line set tube near the small low pressure liquid service valve. The nitrogen will not pressurize the tubing but will push any oxygen out of the tubing during the brazing process. This will also help to dehydrate the lines prior to vacuuming.

5. The technician will then braze the swage joints using a small brazing tip and 15% silver brazing rod. The swage joints will either be behind the indoor head unit, inside the building (while the head unit is tilted upward to gain access to the underside of the unit) or outside the building if the stubs penetrate directly through the outside wall. Make sure to use a heat shield when brazing inside the building or outside near the siding.

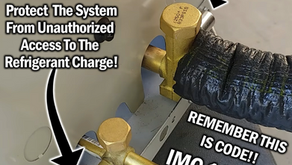

6. The nitrogen will then be disconnected, and the small, low pressure liquid line will be flared and connected to the outdoor unit flare connection. Make sure to tighten all flare connections to the specified foot/lb torque value. Usually this is 12 ft/lb for ¼” OD copper tube and 27 ft/lb for 3/8” OD copper tube, but always follow manufacturers instructions to avoid future leaks or problems at the connections.

7. The system will then be ready for a pressure test to check for leaks.

It’s okay to use flares as connections as long as you are sure they won’t leak. Below is a video on 10 reasons why flares may leak as well as ways to make sure that they won’t.

Let me know your experience if you had to warranty an indoor mini-split head unit with cut off flares. I would love to know if anyone is having any trouble with a warranty based on the cut off flares and with which manufacturer. You can comment below or email me at info@acservicetech.com, thanks!

Check out our book “Refrigerant Charging and Service Procedures for Air Conditioning”.

The full outline is available at https://www.acservicetech.com/the-book

If you have already purchased our book, be sure to tell local HVACR Instructors about our book and what you think of it. We would love to get the book into the hands of the next generation of HVACR Technicians!

Published: 9/12/2019

Author: Craig Migliaccio

About the Author:Craig is the owner of AC Service Tech LLC and the Author of the book “Refrigerant Charging and Service Procedures for Air Conditioning”. Craig is a licensed Teacher of HVACR, Sheet Metal, and Building Maintenance in the State of New Jersey of the USA. He is also an HVACR Contracting Business owner of 15 years and holds an NJ HVACR Master License. Craig creates educational HVACR articles and videos which are posted at https://www.acservicetech.com & https://www.youtube.com/acservicetechchannel

.png)

Mình có vào lại F168 thời gian gần đây và thấy nền tảng thay đổi khá rõ trong năm 2026. Giao diện được làm gọn hơn nên thao tác trên điện thoại cũng thuận tiện hơn trước. Các sảnh trò chơi phân chia rõ ràng nên tìm mục mình muốn khá nhanh. Mình từng ghé trang chủ https://f168.today/ để xem cập nhật thì thấy nội dung được bổ sung đều. Với mình, sự mượt và ổn định quan trọng nhất, nên f168today cũng được nhắc đến nhiều hơn.

Ban đầu mình cũng không quan tâm nhiều đến link chính thức, chỉ cần vào là dùng được. Nhưng sau vài lần gặp lỗi hoặc nhầm trang, mình bắt đầu tìm những nơi cung cấp hướng dẫn rõ ràng hơn. Jun88 là một trong số đó, và khi ghé jun88ncom, mình thấy bố cục gọn gàng, thông tin được trình bày chi tiết, bao gồm cả giấy phép Curaçao và bảo mật SSL 128-bit. Trang nhấn mạnh nội dung mang tính tham khảo, nên mình luôn chủ động truy cập đúng link chính thức. Với mình, sự minh bạch và rõ ràng kiểu này rất quan trọng khi trải nghiệm lâu dài.

Sau những lúc cần nghỉ ngơi để cân bằng lại tinh thần, mình thường chọn xem phim như một thói quen thư giãn nhẹ nhàng. Đôi khi, việc xem một số nội dung dành cho người lớn cũng chỉ là lựa chọn cá nhân, miễn là kín đáo và phù hợp với hoàn cảnh. Mình không chú trọng tìm kiếm quá nhiều, chỉ cần dễ thao tác và cảm giác xem thoải mái là đủ. Trong lúc tham khảo trên mạng, mình có thấy viet69 được nhắc tới ở vài nơi nên cũng biết qua. Với viet69zio, mình vẫn ưu tiên việc tự chọn lọc theo nhu cầu riêng, giữ sự chừng mực để việc giải trí không ảnh hưởng đến…

Mình xem bóng đá để thư giãn nên khá chú ý đến trải nghiệm tổng thể khi theo dõi. Phần bình luận tiếng Việt giúp mình hiểu rõ hơn những tình huống diễn ra trên sân. Khi xem trực tiếp mình nhận thấy socolive tv truyền tải khá đều nhịp trận và các pha bóng quan trọng. Việc truy cập thuận tiện trên điện thoại giúp mình có thể theo dõi ở nhiều thời điểm khác nhau. Với mình, trải nghiệm xuyên suốt là điều cần thiết và socoliveactor vẫn duy trì được sự ổn định đó.

Mỗi khi muốn cập nhật nhanh thông tin về các trận đấu, mình thường ưu tiên những nơi tổng hợp đầy đủ lịch thi đấu, kết quả và bảng xếp hạng, vì nhìn sơ là đã nắm được tình hình chung mà không phải mở nhiều trang. Với kèo nhà cái, mình thường quan sát những tỷ lệ cơ bản và xu hướng chung, không đi sâu phân tích, chủ yếu để có cái nhìn tổng thể. Trên keonhacaifinance, các dữ liệu được bố trí hợp lý, trực quan và dễ đọc, giúp mình nhanh chóng nắm được những thông tin quan trọng mà không cảm thấy rối hay quá tải. Cách trình bày này vừa đủ chi tiết để…